In architecture, strength is never accidental. Every line, every measurement, and every joint tells a story of intent. While railings may look seamless from a distance, their micro-level precision decides real-world safety.

In reality, safety does not exist on the surface. Instead, it is engineered inside every connection. Therefore, when families trust a railing with balance, weight, and daily movement, the margin for error must always be zero.

Where Do Most Railings Fail? Inside the Hidden Joints

Most railings do not fail because they look weak. Rather, failure happens when joint integrity is ignored.

For example, common causes include:

❌ Poor alignment during on-site welding

❌ Uneven tightening or inaccurate drilling

❌ Low-grade connectors and fasteners

❌ Incorrect torque and load distribution

❌ Expansion issues due to heat or moisture

As a result, when the inside is weak, the outside cannot survive. That is exactly where micro-level precision changes everything.

Precision Engineering — Safety You Can’t See, But Can Feel

Premium modular railings, such as Technoraill’s, are built using calculated engineering. Specifically, they rely on:

✔ CNC-machined components

✔ Laser-guided measurements

✔ Consistent fitting accuracy

✔ Zero on-site fabrication errors

Because of this precision, the joints:

• Hold higher loads

• Improve grip stability

• Deliver long-term confidence

Consequently, homeowners experience mega-level safety even if they never see it.

Weather, Vibration, and Time — The True Test

A railing does not remain static. Instead, it faces constant stress every day.

For instance:

• Temperature changes cause metal to expand and contract

• Wind and movement create vibration

• Humidity and coastal air increase corrosion

Only joints built with micro-level precision can:

– Resist loosening

– Prevent rattling

– Maintain balance over time

Ultimately, a railing should never age faster than the home it protects.

When Every Joint Fits Right, the System Performs Better

Just like a luxury timepiece, railing performance depends on its smallest parts.

Without precision jointing, problems appear:

• Wobble

• Noise

• Safety risks

• Visible flaws

However, with precision jointing, you get:

• Unshakable stability

• Silent performance

• Peace of mind

• Seamless elegance

Clearly, beauty that is engineered is beauty that lasts.

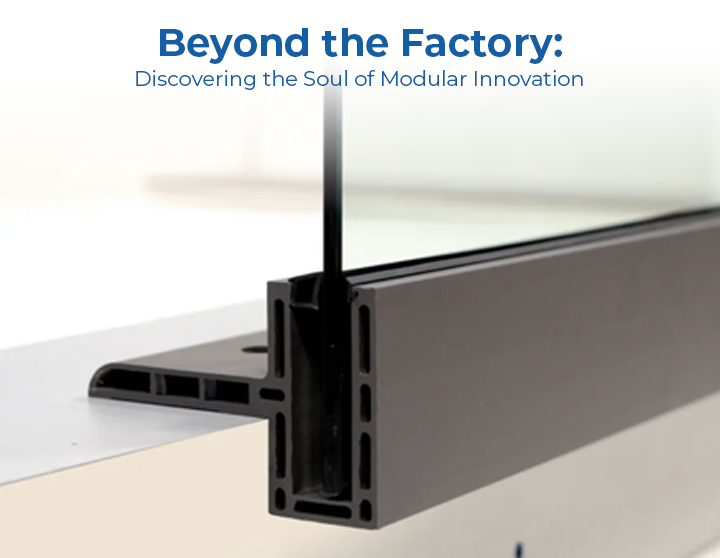

The Technoraill Standard

At Technoraill, every connection point follows strict control. Each joint is:

– Factory-calibrated

– Load-tested

– Inspection-verified

Nothing is left to guesswork. As a result, design aligns with science. Likewise, luxury aligns with reliability. Most importantly, safety aligns with style. This is the promise of true micro-level precision.

Final Word

Mega-structures rarely fail in obvious ways. Instead, they fail at the smallest points no one notices.

Therefore, choose railings where every joint, bolt, and connection is designed to protect your world. Because when you hold a railing, you are not holding metal—you are holding trust.